Workers’ Bodies and Plywood Production: The Pathological Power of a Hybrid Material

Anacortes Veneer, Inc.

Photograph by Ferd Brady. Courtesy of the Anacortes Museum, Wallie Funk Collection.Richard P.’s life might stand in for any one of hundreds of thousands of Americans who crafted a new middle class after World War II. Born in a logging camp near Enumclaw, Washington, in 1927, he began his life in a heavily Scandinavian immigrant working-class community. His father, Hans, worked in a shingle mill, and during World War II he apparently moved his family to Anacortes, another town centered on wood products manufacturing. After graduating high school there in 1945, Richard served his time in the army during the Korean War. Returning home to Anacortes, he got a well-paying job, married a young secretary in 1962, purchased a ranch-style house built in 1958 in a new Anacortes neighborhood, and raised his two daughters.1

Plywood made possible Richard’s class mobility and suburban security. Just as Anacortes Veneer, Inc. (AVI) entered peak plywood production, Richard bought a share that guaranteed him a job in the employee-owned enterprise, and he began work as a sheet turner, building exterior-grade plywood. As output ballooned to fill national needs, Richard’s wages and dividends doubled or quadrupled. For more than thirty years, he continued in plywood manufacturing, drawing wages to support his family. His domestic life centered on his three-bedroom ranch-style house, located near other modest homes, schools, and parks. This house too relied on plywood for its existence; likely its siding, subfloors, and roof underlayment utilized the by-then ubiquitous material (fig. 1). Both physically and financially, the smooth sheets of glued plys gave Richard’s family access to a postwar ideal.2

Fig. 1. The Richard P. family home, Anacortes, Washington.

Tax Assessor.

As Richard’s story illustrates, plywood played an important part in creating and reinforcing a Cold War social structure. Engineered woods acted as agents of change in a time of class mobility. They nurtured the beneficiaries of the post–World War II order, people like Richard—white, working-class descendants of northern European immigrants who entered into the economic comforts of middle-class suburbia. For these Americans, the wood panels facilitated participation in the nation’s newfound prosperity and expanding middle class.3

If plywood could exert creative force in enabling economic betterment, it also wielded the pathological power to destroy. Despite the era’s technological optimism, humans could not fully control or restrain plywood’s fundamental nature. By-products of its synthesized physicality transgressed the boundaries of sleek sheets, of houses’ walls, of factory assembly lines, of zoned landscapes, and of human and animal bodies. The molecules emanating from the material, its manufacture, and its destruction united disparate ecologies into a polluted and hazardous web.4 Plywood’s components potentially affected all Americans, but some suffered disproportionally from the material’s uncontrollable nature. By-products more likely threatened the bodies of those excluded from the middle-class, suburban domestic expansion, such as African Americans, Native Americans, and occupants of mobile homes. Perhaps engineered woods damaged no people as much as they did the employees who labored on their production lines. Plywood mill workers like Richard bore the cost of the potent, pathological agency of the new architectural material.5

Plywood and Its Origins

Plywood’s abilities to both foster a new society and harm its members derived from its hybrid makeup and its central place in home construction. After World War II, the material changed the building industry and its practitioners. Until then, housing consisted of sawn wood—lumber—or manipulated mineral compounds: brick, plaster, metals, concrete. By the 1950s, however, plastic components derived from oil began to replace older materials. A chemical process produced plastics. Under heat and pressure, smaller molecules of phenol or urea and formaldehyde molecules bonded into very long, intermeshed chains called polymers. These polymers formed malleable substances that, when cooled, hardened into stable forms that allowed designers to mold them into useful shapes. By World War II, petroleum and its derivatives had become essential feedstocks for a growing array of plastics. With this new substance, designers and engineers innovated new building materials: laminated surfaces, paneling, flooring, pipes, conduit, and carpet, to name just a few (fig. 2). But most fundamental to construction were engineered woods, especially plywood. A combination of natural fibers and polymer glues (plastics), plywood contained layers of thin, cross-aligned veneers or plys adhered together to create tough, straight panels.6

Fig. 2. Douglas Fir Plywood Association publication, 1954.

Building Technology Heritage Library.

After World War II, this blend of wood and polymer resins dominated domestic construction in the vast suburban landscape of the United States, where three-quarters of the midcentury Douglas fir plywood went to construction and do-it-yourself markets. Residential building in particular consumed about half of all plywood. Substituting board lumber with plywood sheets saved time and money. Slapping up a four-by-eight-foot panel required about half the time it took to pound in nails for one-by-eight-inch sheathing. The price of panels kept dropping as more and more manufacturers sent their products to market. Plywood rapidly replaced lumber in about every way but the essential framing of a structure—sheathing, siding, floor and roof underlayment, cabinets, and counters. The average amount of structural plywood used in an ordinary house jumped from 1,707 square feet in 1950 to 9,668 in 1992. Gradually, post–World War II houses became as much products of chemical companies as of lumber companies.7

The frenetic suburban expansion demanded ever more of this hybrid material. From the 1950s to the early 1970s, petrochemical houses set off a boom in the plywood industry. Every year after 1947, the industry broke production records. The growth occurred largely in softwood plywood—veneers of coniferous trees—but one species dominated. Douglas fir provided 95 percent of the wood for plywood, and the species grew predominantly in the Pacific Northwest. There, concentrated stands of old-growth trees yielded valuable “peeler” logs—trees of great girth with smooth boles, fast-drying fibers, and few blemishes. “Softwood” plywood became synonymous with Douglas fir plywood. Average yearly production of it grew by 14 percent between 1947 and 1962. In 1955, 158 mills in the western states rolled out Douglas fir plywood. By 1954–55, 24,000 men (and some women) in 100 plywood mills were transforming logs into 3.9 billion feet of panels. Between 1958 and 1971, employee numbers swelled to 73,700, reaching their peak in 1966 as the Vietnam War buildup stimulated demand. In these years, virtually all of these workers labored in mills along the coasts of Washington, Oregon, Northern California, and British Columbia.8 At these production sites, the employees dealt with the organic realities of Douglas fir.

Manufacturing Process

As much as modern engineers designed plywood manufacturing to exert control over production, the material itself dictated fabrication processes. Harvesters had to adapt to the wood’s independent nature. Although plywood could consist of either hardwoods (deciduous) or softwoods (coniferous), lumber companies considered Douglas fir the preferred species. A native of the coastal and interior US West, these trees consisted of a tough, long-fibered, rot-resistant wood ideal for structural lumber. The material’s strength made it particularly well suited for yielding plys—thin, continuous sheets of wood carved from the tree’s bole. Douglas fir’s beautiful pink and amber coloring was an added bonus. Along the West Coast, these trees grew to immense size and weight, commonly reaching 250 to 300 feet in height and 5 to 8 feet in diameter. These characteristics conscribed its logging and hauling. Where possible, and especially before tree scarcity forced loggers farther inland, water moved the massive trunks. Floated in booms on natural waterways from the forests, the fir logs entered ponds at the mill. In the interior West, trucks hauled smaller logs to decks where sprinklers kept the wood wet to prevent checking and staining. Cut into 6- to 12-foot lengths and then mechanically debarked, the heavy logs entered the “green” end of a plywood mill. The organic qualities that made Douglas fir so desirable also constrained its harvest and directed its movement.9

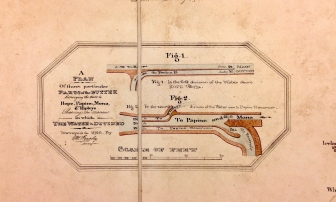

Where size and weight were the main concerns for getting trees like Douglas fir to factory sites, their other organic characteristics dominated the milling process. Factory designers had to accommodate these natural features. In places like Anacortes, Washington, logs soaked in salt water (fig. 3). Inland, at Bonner, Montana, they went to steam-heated vats of hot water and caustic soda, where they lay for six to eight hours. Softening was crucial; in winter, the fiber was so tough it could knock off chunks of the steel lathe knife. Chain grapples or overhead cranes lifted the heavy bolts to the de-barkers and lathes (fig. 4). In Bonner, the tree species determined which of four lathes peeled the plys; each species’ characteristics demanded different technologies. Workers secured the blocks into a lathe with a pressure bar that pushed it against a long, sharp knife (fig. 5). Calibrated to a specific thickness, the lathe rotated, and the knife sliced off a thin ribbon of wood (fig. 6). Ideally rolling out in a continuous strip, the sheet moved along a conveyor, where guillotine-like clippers cut the ribbon to standard lengths (fig. 7). Sorted and graded, the best pieces went to dryers that subjected the veneers to high heat—350 degrees Fahrenheit—to drive down their moisture content (fig. 8). If the dryer was too hot, the fabric could become hard and brittle. If the fabric was too damp, the excess water created steam pockets when pressed. Mill hands then sorted the veneers for quality, cutting out blemishes and plugging in patches. Ready for gluing, the plys moved into the lay-up end of the factory. Sometimes in a separate structure, glue specialists combined the chemicals needed for the resin in mixers and pumped it back to the spreader area. Four-person crews in the assembly area put the panels together (fig. 9). One worker put the dried core material into a glue spreader that coated both of its sides. Exterior or face plys received glue on one side. Onto a back sheet, another person laid the cores in crossband layers with the grain of one layer perpendicular to the next. The other two crew members applied additional plys and face veneers to build a typical five-ply sheet. The panels then entered the hydraulic press, where intense heat and pressure set the glue and triggered polymerization that created a bond between resin and wood. How long the sheets remained depended on the tree species (fig. 10). Cooled and with the adhesives set, plywood entered its finishing phase. Trimmed to four by eight feet, sanded, and sorted, the plywood sheet headed to storage on forklifts to await shipment. Though the manufacturing process seemed a model of efficient control, at every step it had to accommodate to the wood.10

Fig. 3. Anacortes Veneer, Inc., aerial view, 1951.

Courtesy of the Anacortes Museum.

Fig. 4. De-barking a log at Anacortes Veneer.

Courtesy of the Anacortes Museum.

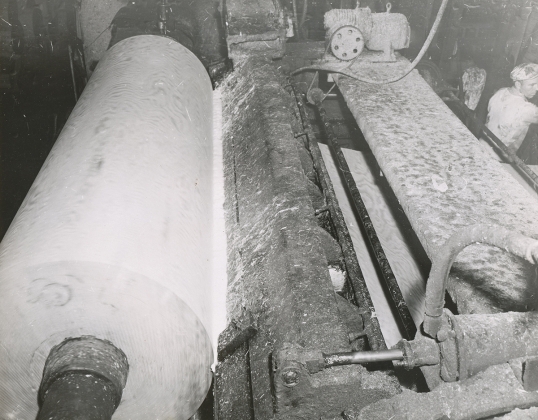

Fig. 5. Veneer lathe peeling a log.

Courtesy of the Anacortes Museum.

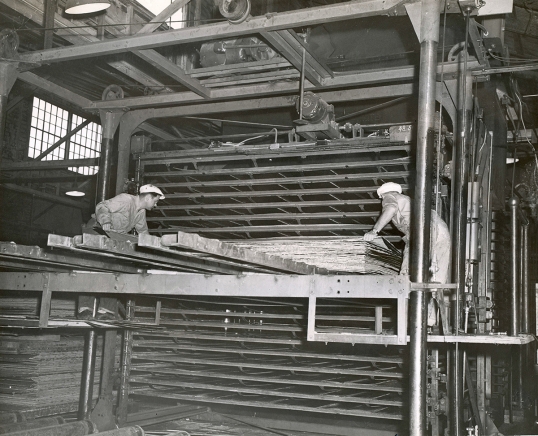

Fig. 6. Unidentified workers at Anacortes Veneer.

Courtesy of the Anacortes Museum.

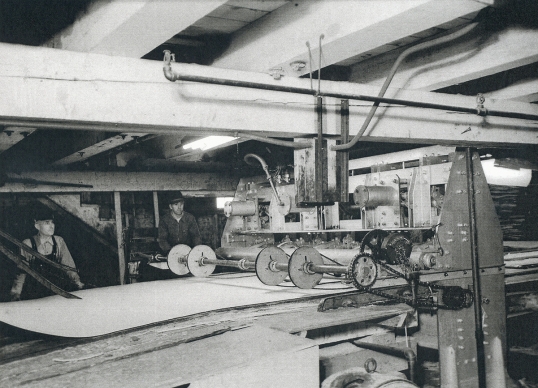

Fig. 7. Saw cutting veneer plys into strips at Anacortes Veneer.

Photograph by Ferd Brady. Courtesy of Anacortes Museum, Wallie Funk Collection.

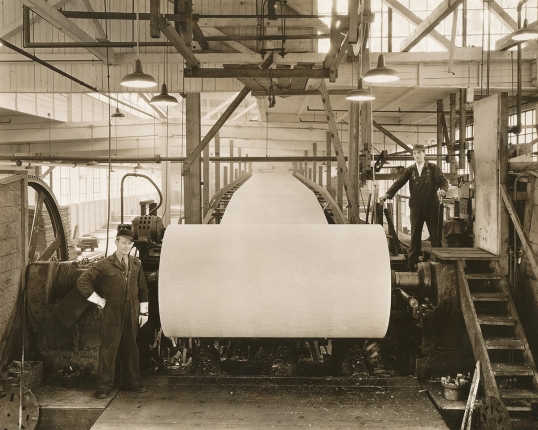

Fig. 8. Dryer at Anacortes Veneer.

Courtesy of the Anacortes Museum.

Fig. 9. Anacortes Veneer glue spreader and sheet lay up.

Photograph by Ferd Brady. Courtesy of the Anacortes Museum, Wallie Funk Collection.

Fig. 10. Hot press at Anacortes Veneer, 1950s.

Courtesy of the Anacortes Museum.

Mill owners considered plywood part of Fordist production control, cost efficiency, and profit accumulation. On site, however, the organic “unruliness” of wood thwarted smooth flow from the raw to the finished state. Its nature resisted capitalistic domination. Each species had its own attributes and drawbacks, each tree its irregularities, and each panel its flaws and idiosyncrasies the assembly line had to address. Production was not always seamless. Wood’s unpredictable organic idiosyncrasies could interrupt any machine-like efficiency. “Plug-ups” in the process were common. For instance, automatic feeders propelling veneers into the dryers might send multiple sheets stuck together rather than single sheets. The thick plys jammed up the dryers and could start fires. Plug-ups at the stacker created frustrating messes of “crumpled” veneers. The peeler log in the lathe might “split out” when the knife encountered hidden rot. Slivers sometimes jammed between the knife and nosebar, destroying the veneer and stopping the line. The plys needed constant monitoring for moisture so they did not become too brittle in the dryers or too wet for efficient gluing. Employees had to handle the thin ribbons delicately so as not to break them. Young trees sometimes yielded “wavy” veneers that failed to evenly adhere. If laid up while still damp, the panels could develop blisters that exploded during hot pressing. The hybrid material defied its regimentation, and when it resisted, the assembly line had to acquiesce to the wood’s nature.11

Workers’ Bodies and the Manufacturing Process

To produce plywood, the bodies of workers conformed to the industrial process that the material’s components dictated. Though as mechanized as possible, plywood production still involved muscle power and human attention to the vagaries of wood. At the mill, human biology intersected with engineered wood’s demands.

Making plywood required arduous physical effort even though continuing mechanization through the twentieth century reduced the amount of manual labor. Once the veneer unrolled from the lathe, the conveyor moved it rapidly and relentlessly down the line. Machines and profit margins influenced the pace but so too did the nature of the wood and the plastic resins. As the men and women working on the line adjusted to the demands of the wood and the production flow, their bodies responded. Much of the labor consisted of lifting and moving heavy plywood sheets. Some jobs were more strenuous than others; core layers, for instance, hand-built the plywood sheets at the glue spreader by piling up the veneers. They had to carefully handle the veneers to ensure high-quality products but move quickly to keep up the rate of production and thus profitability. Managers considered younger men appropriate for these jobs. Taking veneers from the dryers was another onerous task. As a mill hand noted, “it comes out of the dryer. It comes onto the table … you got to figure you got four rows coming at you or some of the dryers have five rows coming. So within a few minutes you’ve got eight to ten pieces of things coming at you on that table and you have to keep that table cleared or try to because the next batch is coming right after it. It doesn’t wait for you to clear the table.” Expressing the stress of the assembly line, one worker said, “There are times when it’s so fast you can’t hardly keep up … times when I want to just cry so I can go drink a Coke or take a smoke.” Although the machine tenders such as the lathe operator, the dryer lead worker or glue spreader had more expertise, most plywood jobs required endurance and strength. Particularly in employee-owned mills like the one where Richard P. worked, crew members rotated jobs so that in time almost everyone could step into a wide variety of positions. In unionized plants, personnel sought new positions within the plant through bidding on open jobs and selection based on seniority. This provided some variation on a machine-driven work process that was exhausting and boring. “You’re doing something that’s basically unpleasant… . Most jobs are monotony and repetition. It can drive you nuts,” observed a fatigued employee. Plywood’s nature commanded the energy of its builders.12

It also required mental acuity, skill, and knowledge of the logs’ individual qualities. On the “green chain,” the material not only necessitated muscle power but the rapid assessment of the wood’s vagaries and natural properties. As explained by Pete Richardson, the green chain conveyor picked up the short or flawed pieces of veneer that remained after the clipped, full-sized sheets went to the stacker. Mill hands stood on either side of the rapidly moving belt and pulled off all segments still useful, called “strip,” for cores. The “junk” not removed went to chippers and became fuel or feedstock for paper or particle board. Workers had to make very rapid analyses of what passed before them, separating species, sapwood or heartwood, and degrees of frayed imperfections called “fishtails” into separate bins. Each category required more specific handling down the line. Different species dried at different rates, sapwood contained more water than did heartwood, and fishtails needed trimming, patching, or stitching together. Automation could not replace humans on the green chain. Sorting the strip required quick evaluations of wood characteristics, subjective decisions about quality, and deft handling of delicate veneers. The “key to the green end labor process at the mill,” said Richardson after his stint on the green chain, was the experienced laborer’s understanding of the “holistic qualities of the wood.”13 In sorting the strip, the men (in his study) made decisions and moved their bodies according to the material. As a co-worker told Richardson, “the wood tells you how to pick it up.”14 In response to the strip pieces’ sheen, color, and imperfections, workers used their whole bodies and senses to “pull chain.” As Richardson noted, “every piece of wood requires a slightly different stance of the body, pressure applied through your glove, force of motion as the wood is brought into the cart.” Aided by experience with the material’s organic qualities, bodies moved to the agency of the wood.15

Effects of Plywood on Workers’ Bodies

For some mill hands, their hard, physical work building plywood yielded benefits. By giving them a foothold in the postwar suburban middle class, the material nurtured workers like Richard P. The industry flourished after World War II and created well-paying jobs that allowed a comfortable standard of living. For instance, Richard’s workplace, Anacortes Veneer, Inc. (AVI), in Washington State, was reportedly “one of the largest and most modern plywood plants on the Pacific Coast,” and it reaped the rewards of the postwar building expansion. Established in 1939, the employee-owned factory erected a plywood facility that followed “the newest and most modern principles of the industry.” The sawtooth-roofed facility spread out on piers over 2.5 acres of tidal land on the site of a former box factory. Inside the 127,000-square-foot floor space, “endless conveyor belts” allowed for the efficient flow of veneer from lathe to finished panels held in storage.16 The location of these state-of-the-art facilities and the timing of their construction ensured that AVI made large profits when suburban development exploded across the United States.17 The owners worked for themselves, not a corporation. In 1939, men who could invest $2,000 bought shares in the fledgling venture. This guaranteed them jobs in the mill, and when the plant began to turn a profit, the worker/owners received dividends in the form of wage increases. While conventional plants paid workers an average of $1.95 per hour, co-ops like AVI paid $3.00 to $3.50 an hour. After World War II, as output ballooned, worker/shareholder wages and dividends doubled or quadrupled, making these AVI personnel what Saturday Evening Post called “the richest mill hands in the country.” By 1951, original shareholders had seen the worth of their $2,000 investment rise to around $28,000.18 Plywood gave AVI co-op members like Richard the ability to live in new ranch-style houses and support baby boom families. In this way, engineered woods dispersed the benefits of the Cold War power structure to the Pacific Northwest’s white working class.19

Deleterious Effects of Plywood on Workers’ Bodies

However much well-paying plywood jobs might nourish mill workers, plywood also had the power to destroy them. The physical labor of creating plywood abused human flesh, most commonly through musculoskeletal trauma. Although mechanized, assembly required strenuous manual labor: quick, repetitive movements, as well as lifting, moving, sorting, and stacking heavy sheets, pushing loaded handcarts, and maneuvering large logs. The equipment demanded maintenance that wrenched bodies into odd contortions. Sprains, strains, and tendonitis in upper extremities—arms and hands—and sore backs especially plagued workers. Cuts and bruises from striking equipment or objects slamming into bodies sent employees to medical facilities for their wounds. To a lesser extent, falls broke bones and damaged knees and ankles, and moving parts, such as chippers, severed fingers. Plywood mills were excessively hot in the dryer area and so loud they could bring on deafness. Near the pneumatic chippers, workers could not communicate by voice. Workers might recover from these sorts of wounds, but some workers died, their heads crushed in machinery or their bodies smashed by logs or equipment. Others became pinned in presses or burned in fires. A few experienced especially tragic and gruesome deaths. One worker, Frankie Crispen, fell into a vat of hot, caustic water for softening logs and died instantly. Only after the liquid cooled the next day could emergency personnel recover his body for his grieving family. 20 Worker-owned plants like AVI were especially dangerous. Rather than selling their labor as a commodity to an indifferent corporation, AVI’s shareholders/employees acquired the fruits of the labor directly in higher wages. With incentives to work harder and longer, the company achieved greater production, which, in turn, led to noticeably higher injury rates.21 Transforming organic materials into plywood and extracting profits from nature was a violent—even deadly—process for those who labored within it.

Along with the machinery, the wood itself damaged plywood workers. Splinters—not little ones found in fingers but long shafts—split from blocks and impaled flesh like spears. Veneer pieces ejected from the belts pierced employees’ bodies. Wood dust was a constant problem; the barkers, cutters, trimmers, and especially sanders spread a fine layer throughout the plant, and it required constant maintenance. The wood dust accumulated along the belts and in the equipment where it occasionally exploded into flame. Plywood mill fires occurred with frightening regularity. With dust came mold and fungi spores and chemicals from the heartwoods (terpenes and abietic acid). When operators inhaled, the particles clogged their lungs, diminished their lung function, and provoked allergies, hypersensitivity pneumonitis, and “woodworker’s asthma.” Their breathlessness and symptoms might have felt like the flu—coughing, runny nose, “headache, chills, sweating, nausea … fever.” Even worse, “organic” wood dust potentially invaded and altered the most interior environment: the DNA in human cells. Scientists implicated Douglas fir dust as a cause of nasopharyngeal cancer.22

The synthetic aspects of plywood endangered bodies in more insidious ways. Formaldehyde-based glues derived from petrochemicals held the veneer sheets together. In US Plywood’s Bonner, Montana, plant, specialists combined phenolic resin with other ingredients, such as soda ash, blood, and flour, in a “glue loft.” The mixture went to the gluing machines that coated the sheets. Along with the wood itself, plywood’s glue attacked human organs. Skin suffered from the chemicals and the woods’ oils. Particularly when uncured, urea-formaldehyde and phenol formaldehyde resins sometimes caused “glue itch,” or dermatitis. During World War II, this malady affected many mill employees, whose symptoms ranged from cracked skin on fingers to “swelling, blistering and oozing of the skin.” In 1951, a sheet turner at St. Paul and Tacoma Lumber Company spent two months hospitalized to receive “extensive medical care” after he developed “violent exfoliative dermatitis” that he claimed resulted from exposure to glue. Sometimes fatal, this condition featured red, inflamed skin that sloughed off in sheets and could require treatment in burn centers. Covering his hands, forearms, and legs, it rendered him unemployable at least until 1953. Some species of wood, especially western red cedar, also induced an irritant form of dermatitis.23 As chemicals in plywood resisted their control, they attacked the external barriers of the workers’ skin.

More insidiously, plywood glues created a polluted environment inside mill workers’ bodies. Phenol or urea resins incompletely polymerized with formaldehyde in the hot presses. Some unattached formaldehyde molecules always remained, and they spread into the air. In the mills, free formaldehyde diffused into the workers’ lungs and bloodstreams. A highly reactive substance, it metabolized quickly in the body, bonding easily with proteins and nucleic acids. The gas made people’s eyes sting and gave them coughs, cold-like symptoms, headaches, rashes, chest pains, diarrhea, and nausea. Neurobehavioral symptoms such as extraordinary fatigue and insomnia might ensue. The formaldehyde, not just wood dust, caused asthma in some plywood workers. In New Zealand, they experienced lung disorders, chronic upper respiratory tract infections, coughing, phlegm, and asthma. But worse, formaldehyde was a known human carcinogen able to cause tumors in the nose, sinuses, and pharynx and, to a lesser extent, leukemia. Particularly near the presses, formaldehyde from glues permeated the workplace air. Employees in those areas inhaled high concentrations of free formaldehyde molecules, increasing their cancer risk with every breath. In fact, laborers in the engineered woods, hardwood, and flooring mills had the highest exposure to formaldehyde. The molecules penetrated human tissues, attacked biological systems, and potentially reorganized cells’ DNA. Mill hands like Richard P. got a double dose of the off-gassing. Subjecting his body to a polluted factory environment, he then returned to a petrochemical house with its own plywood potentially emitting formaldehyde fumes. Plywood remade the environments of the factory, the modern home, and the mill worker body.24

Plywood Pollution of the Landscape and Bodies

Clearly, efforts to control plywood’s wild nature failed to restrain its transgressive properties. Even factory walls could not contain its unruly nature. Plywood’s ability to harm life extended beyond the mills to the landscapes within which they lay. Once the detritus of plywood moved outside the plant, it joined toxic molecules to local peoples’ bodies. Where plywood went, potentially dangerous molecules followed, linking the domestic, the production, and the ruins in a noxious web.25

Anacortes, Washington, serves as an example of plywood’s unbounded effects. There, the most obvious and annoying evidence of plywood’s pollution was smog. Air quality suffered from the fuel burners of Publishers’ Paper Company, the firm AVI sold out to in 1969. To provide the heat needed for dryers and presses, the plywood plant utilized its most abundant energy source: waste wood, which often failed to burn completely. Compounding the smoke that inefficient burning created were salt residues left in the wood from its soak in seawater. When burned, these salt-contaminated wood scraps emitted sodium chloride particles that created a cloudy plume. In Anacortes, the area’s 40 percent opacity of the air violated the Clean Air Act standard of 20 percent. The Environmental Protection Agency considered these particulates potentially harmful, although mill owners claimed that they were of “no proven harm and therefore should not be considered a source of pollution.” In the late 1980s managed by a new company, the old, outdated burner failed to arrest smoke particles, and the mill stack spewed what looked like a “‘torch on the Fourth of July’” (fig. 11). In 1988 and 1989, the Northwest Air Pollution Authority (NWAPA) received many complaints about “greasy, black cinders” falling on boats in the nearby marina. The black material permeated the fiberglass coatings, leaving a “sticky soot.” The NWAPA control officer claimed that the air pollution was merely a nuisance and not “hazardous to the public health.” Making the smog even worse, combusted phenol formaldehyde glue sediments combined with the wood smoke. After these precipitates fell out from glue wash water during production, workers trucked them to the hog fuel pile and threw them into the flames.26 Even in its destruction, plywood exerted its agency to transform environments. Its power moved beyond the lives of mill workers and into bodies of all classes of people and creatures that breathed the local air.

Fig. 11. Parking lot of Anacortes Veneer.

Courtesy of the Anacortes Museum, Wallie Funk Collection.

Anacortes residents could see the smog. More insidious was plywood’s pollution that Anacortes inhabitants could not readily see. Through the years, various plant owners had dumped wastewater from plywood processes onto the tidal flats and directly into Fidalgo Bay: water from the dryers, containing phosphorus, sodium, oil, grease, and phenols; water from the boilers; water from phenol-formaldehyde glue; water that cooled the hot presses; water used to clean up caustic spills. Hydraulic oils from the presses, lubricating oil from the hog fuel burners, and glue (both solid and liquid) soaked into the ground surrounding the plant. These effluents washed out into the bay, where they joined pollution from oil refineries, a tank farm, a paper mill, and boat-building docks.27 Like air, fluid and uncontrollable, water spread these petrochemical by-products into another realm and transformed the aquatic ecosystem.

The full extent of contamination spreading beyond the former AVI mill site came to light in the 1990s (fig. 12). After a fire in 1992 destroyed the mostly empty structure, the site became valuable waterfront property, and it attracted speculators. But development could not proceed until cleanup occurred. In 1993, under the Voluntary Cleanup Program, a long series of environmental reviews began. They resulted in remediation in some places. Continuing investigations into the groundwater and soils, both above and below the tide line, determined the extent of the pollution beyond the factory walls.28

Fig. 12. Plywood mill ruins, 1999.

Courtesy of the Anacortes Museum.

As might be expected, petrochemical hydrocarbons from plywood production poisoned the environments surrounding the mill. Around the old press pits, compressor house, hardboard plant, and hog fuel burner, heavy oils—diesel, hydraulic, and lubricating—from leaky equipment had contaminated the earth. In 1992, one observer had reported “deep pools of heavy oil” under the mill. Near the boiler house lay polychlorinated biphenyl compounds (PCBs) associated with a transformer station and inorganic elements from paint and metal equipment. Decrepit creosoted pilings left carcinogenic polycyclic aromatic hydrocarbons (cPAHs). Old resin tanks tested for formaldehyde and phenols before their removal in 1997, and sediments in the plant’s vicinity revealed phenol compounds. Diesel oil showed up in the groundwater.29

The organic part of plywood—wood—also contaminated the beach and changed its composition. Wood debris covered the area in depths from five to twenty feet. Where the mill once stood, burned building materials, brick, and concrete littered the area. At the lower end, deep piles of sawdust and scattered logs marked the decades that the plant had dumped its wood waste onto the tidal flats and into the water. Wood residue extended approximately three hundred feet out from the shoreline and tainted the ground and water more extensively than the petroleum products. As the wood waste decayed, it released toxic contaminants—sulfide, ammonia, phenols—that reduced oxygen in the water, killing the native eelgrass and the organisms that depended upon it.30

Worse, dioxins and furans, produced in the incomplete combustion of wood and the engines of diesel and gasoline vehicles, permeated the soil. These contaminants probably originated from the three historic fires that had destroyed buildings on the site. Dioxins existed in different forms, the most toxic of which the EPA categorized as a “human carcinogen.” Other dioxins, such as those found at the Anacortes mill, the agency categorized as “likely human carcinogens.” Well known as toxic to animals, dioxins accumulated in tissues and could detrimentally affect reproduction, suppress the immune system, and cause cancer. Now transformed by fire, the molecules from plywood had spread to the earth, to the water, and to the organisms that lived there.31 Even with the mill in ruin, plywood could kill.

Through air, water, and earth, plywood’s pathological power escaped the factory walls and harmed people who had received few benefits from the post–World War II era’s prosperity that plywood production had helped deliver. The harm was unequally distributed, and tribal peoples potentially suffered more than white residents of Anacortes. Toxins like dioxin accumulated in fish and shellfish after the animals ingested the polluted sediments and stored them in their fat. When people ate the shellfish—crab and clams in particular—plywood’s by-products entered human tissue. In Fidalgo Bay, locals—especially the region’s Native people— harvested the tidewater animals. When tribal members continued their traditional subsistence practices or augmented their household economies with fish and shellfish, the chemicals from plywood menaced their bodies. The toxins especially threatened the Samish tribe, who lived in the Anacortes vicinity; the Swinomish tribe, whose reservation lay to the east of Fidalgo Bay; and the Lummi, Upper Skagit, and Suquamish. These people had long foraged through the San Juan Islands to maintain a diet rich in salmon and shellfish that they gathered along the shorelines and from the waters. Agreements gave them the right to fish and harvest shellfish at their “usual and accustomed grounds and stations” around Puget Sound. Both the Swinomish and Samish tribes considered Fidalgo Bay “an important historic harvest site.” Commissioned by the tribes, tests on the clam beds and crabs from the region revealed the presence of PCBs, polyaromatic hydrocarbons, and dioxins/furans (among other toxins) in the shellfish tissue. Because of tribal peoples’ higher rates of shellfish consumption, the pollutants left by plywood inordinately threatened their health. These toxins most endangered the smaller and physically developing bodies of children. Unbounded by space and time, the harmful molecules from plywood extended their reach into the future.32

Plywood’s Legacy

Plywood lay at the center of a great web of environments: suburbs, seashores, forests, factories, and bodies—human and nonhuman. The hybrid material could nurture a family like Richard P.’s, and it could menace Native children foraging along Fidalgo Bay. It exerted a double-edged power. Perhaps Richard experienced the ambivalent consequences of plywood. A lifelong boater, outdoorsman, and “very active walker” after retirement, covering more than twenty miles a week through various Anacortes neighborhoods, Richard was a fit man. Yet in 2007, he succumbed to complications of kidney cancer at age seventy-nine.33 We will never know if his disease resulted from his decades in plywood mills or his forty-five years in a ranch-style house made of engineered woods. But we do know that plywood had the power to thwart human control, to transcend imposed boundaries, to reshape environments, and to transform the innermost biology of living creatures.

Plywood’s agency to influence the course of history leads us to reconsider our approach to vernacular architectural history scholarship. By “reading” architecture as text, we have sought to know its creators’ minds and the ideas that both reflected and directed behavior. In this view, cultural constructs continually shaped and reshaped people and so directed history. However, ideas alone fail to explain historical change; the biogeophysical world exerts a powerful force. Plywood had its own inherent qualities, needs, and demands. Accommodating to this material reality exacted a price; both plant workers and people consuming contaminated seafood disproportionately suffered from plywood production. Across the nation, neighborhoods of ranch-style houses built of this hybrid material were born of working peoples’ pain.34

From this perspective, the materiality of architecture becomes a powerful, not-always-benign historical force. The built environment can exert a pathological influence, transforming places that nurture life into ones that insidiously destroy it. People make architecture, and they innovatively craft its components. But those who labor to create the artifice cannot escape unruly nature and the violent processes of transforming it.

✓ Transparent peer-reviewed

Janet Ore, “Workers’ Bodies and Plywood Production: The Pathological Power of a Hybrid Material,” Aggregate 10 (June 2022), https://doi.org/10.53965/CPGG8794.

- 1

The editors and I chose to omit his last name and remove personally-identifying details in this text in consideration of his survivors. Richard P. obituary, Anacortes American, June 30, 2007; “Richard P.,” Northrup Family Tree, Ancestry, accessed June 21, 2021, https://www.ancestrylibrary.com/familytree/person/tree/16680278/person/543320560/facts?_phsrc=dwN875&_phstart=successSource. Undoubtedly, Richard P. is among many Anacortes residents who worked at AVI and lived in a ranch-style house. I chose him at random because I could place him in a ranch-style house and obtain biographical information for him.

↑ - 2

Richard P. obituary; Tax Assessor, Property Search P57610, 1915 Twenty-Third Street, Anacortes, Skagit County, WA, accessed September 7, 2021.

↑ - 3

Dianne Harris, Little White Houses: How the Postwar Home Constructed Race in America (Minneapolis: University of Minnesota Press, 2013). Harris makes clear that the Cold War domestic ideal worked to create a white, middle-class identity for families like Richard P.’s that excluded racialized groups.

↑ - 4

Michael Egan, “Mercury’s Web: Some Reflections on Following Nature across Time and Place,” Radical History Review 107 (Spring 2021): 111–26. My interpretation of the agency of material culture and vernacular architecture arises from the melding of two fields: material culture studies and environmental history. Since these literatures are large, I will include here the works that I consulted for this chapter. See Karen Harvey, “Introduction: Practical Matters,” in History and Material Culture: A Student’s Guide to Approaching Alternative Sources, ed. Karen Harvey (London: Routledge, 2009), 1–23, for a good overview of material culture studies historiography; Annabel Jane Wharton, Architectural Agents: The Delusional, Abusive, Addictive Lives of Buildings (Minneapolis: University of Minnesota Press, 2015); Mark Fiege, The Republic of Nature: An Environmental History of the United States (Seattle: University of Washington Press, 2012); Timothy J. LeCain, The Matter of History: How Things Create the Past (Cambridge: Cambridge University Press, 2017); Nicole Boivin, Material Cultures, Material Minds: The Impact of Things on Human Thought, Society, and Evolution (Cambridge: Cambridge University Press, 2008). My article, Janet Ore, “Viewpoint: Landscape Disputed What Environmental History Can Show Us,” Buildings and Landscapes 27, no. 2 (2020): 5–18, more clearly explains my melding of environmental history and vernacular architectural studies.

↑ - 5

My interest in how plywood remade the working, domestic, and bodily environments of working people stems from my previous work about the toxic interiors of mobile homes. See Janet Ore, “Mobile Home Syndrome: Engineered Woods and the Making of a New Domestic Ecology in the Post–World War II Era,” Technology and Culture 52, no. 2 (2011): 260–86.

↑ - 6

For a comprehensive history of plywood, see Christopher Wilk, Plywood: A Material Story (London: Victoria and Albert Museum/Thames & Hudson, 2017); Jeffrey L. Meikle, American Plastic: A Cultural History (New Brunswick, NJ: Rutgers University Press, 1997), 31–41, 64; Encyclopaedia Britannica (15th ed.), s.v. “Industrial Polymers,” 9-504; Fabrizio Cesaroni, Alfonso Gambardella, and Myriam Mariani, “The Evolution of Networks in the Chemical Industry,” in The Global Chemical Industry in the Age of the Petrochemical Revolution, ed. Louis Galambos, Takashi Hikino, and Vera Zamagni (Cambridge: Cambridge University Press, 2007), 33; and John Kenly Smith Jr., “The American Chemical Industry since the Petrochemical Revolution,” in Global Chemical Industry, ed. Galambos et al., 175, 177.

↑ - 7

Katrina V. Berman, Worker-Owned Plywood Companies: An Economic Analysis (Pullman: Washington State University Press, 1967), 30, 31–32. By the 1960s and 1970s, an even more synthetic material had begun to usurp plywood: particle board. It consisted of a mash of wood fibers and resins extruded from machines and hardened into sheets. David B. McKeever and Robert B. Phelps, “Wood Products Used in New Single-Family House Construction: 1950 to 1992,” Forest Products Journal 44 (November–December 1994): 71–72, 73.

↑ - 8

John A. Guthrie and George R. Armstrong, Western Forest Industry: An Economic Outlook (Baltimore: Johns Hopkins Press, 1961), 125–7, 131; Berman, Worker-Owned Plywood, 20–21; Robert M. Cour, The Plywood Age: A History of the Fir Plywood Industry’s First Fifty Years (Portland, OR: Douglas Fir Plywood Association, 1955), 140, 169, 160; Mary Robinson Farris, “The Veneer and Plywood Industry: Above-Average Productivity Gains,” Monthly Labor Review 101 (September 1978), 26. Each year in the 1950s, plywood production rose 13.5 percent. Of this, 75 percent went to building and construction, while new residential construction constituted 41 percent that proportion in 1955. “Plywood Industry Aims to Double Its Sales in Next 10 Years,” American Lumberman and Building Products Merchandiser 19 (December 1960): 32. In 1954, a peak year, 100 plants produced over 3.9 billion feet of Douglas Fir plywood. Cour, Plywood Age, 140, 145. The demand for plywood remained strong until the 1970s recession, increasing production an average of 5.3 percent each year between 1958 and 1971. Farris, “Veneer and Plywood Industry,” 26.

↑ - 9

For more on this amazing tree, see Stephen F. Arno and Carl E. Fiedler, Douglas Fir: The Story of the West’s Most Remarkable Tree (Seattle: Mountaineers Books, 2020); Montana State Department of Health and Environmental Sciences, Environmental Sciences Division, Air Quality Bureau, “Environmental Impact Statement on the Proposed Plywood Manufacturing Plant at Bonner, Montana,” April 30, 1973, p. 2-5, accessed in Mansfield Library, University of Montana, Missoula (hereafter cited as EIS Bonner Mill); and Otis Seal, retired millwright, in Plywood Plant, Working the Mill Series, part 5, DVD 5301, Bonner Area History Roundtable, accessed in Special Collections, Mansfield Library, University of Montana, Missoula.

↑ - 10

Otis Seal, in Plywood Plant DVD; EIS Bonner Mill, 2-4; Pete Richardson, “Green Chain Work in a Western Mill” (PhD diss., Emory University, 2002), 358–60; Berman, Worker-Owned Plywood, 39–43; Guthrie and Armstrong, Western Forest Industry, 136–37; Henry Spelter and George Sleet, “Potential Reductions in Plywood Manufacturing Costs Resulting from Improved Technology,” Forest Products Journal 39, no. 1 (1989), 8–12; “Plywood and Veneer Industry,” typewritten sheet in “BIM Plywood Mill History File” clipping file, Anacortes Museum; James Callan, interview by Alexander Dunn, July 11, 2002, Anacortes Museum; Arthur F. McEvoy, “Working Environments: An Ecological Approach to Industrial Health and Safety,” supplement, Technology and Culture 36, no. 2 (1995): S145–73.

↑ - 11

Richardson, “Green Chain Work,” 162–63, 171–73, 184; Spelter and Sleet, “Potential Reductions in Plywood Manufacturing Costs,” 9–11.

↑ - 12

Edward S. Greenberg, Workplace Democracy: The Political Effects of Participation (Ithaca, NY: Cornell University Press, 1986), 42, 81–84 (quotes, 82). Two videos give a clear depiction of the speed and physicality of historic plywood production. See 1954 production in “Manufacturing Plywood Boards: Then and Now,” Victoria and Albert Museum, accessed on YouTube, June 29, 2021, https://www.youtube.com/watch?v=eF5LVBW1vl8; on 1920s production work, see “Harbor Plywood Historic Film from Schafer Bros,” Washington State Archives, accessed June 29, 2021 at https://www.youtube.com/watch?v=yrisN16mJX0. See also Richardson, “Green Chain Work,” 184; Gunther Peck, “The Nature of Labor: Fault Lines and Common Ground in Environmental and Labor History,” Environmental History 11, no. 2 (2006): 212–38; and Berman, Worker-Owned Plywood, 155, 58.

↑ - 13

Richardson, “Green Chain Work,” 160.

↑ - 14

Richardson, “Green Chain Work,” 174.

↑ - 15

Richardson, “Green Chain Work,” 182. For an example of this work, see “Pulling Green Chain,” at YouTube, accessed June 29, 2021, https://www.youtube.com/watch?v=0_w307HU2-Q; and see also Richardson, “Green Chain Work,” 150–60, 182, 203–5.

↑ - 16

Berman, Worker-Owned Plywood, 25; “Anacortes Plywood—A Leading Industry of the Northwest,” unidentified newspaper clipping date September1938; and “Anacortes Plywood to Begin Construction,” Anacortes American, November 15, 1937, both in “BIM Plywood Mill 1940s” clipping file, Anacortes Museum.

↑ - 17

“Anacortes Veneer Company,” Plywood Pioneers Association, No. 18, published in 1978, (copyright 1970), n.p., accessed October 18, 2021, at https://www.apawood.org/data/Sites/1/documents/monographs/18-anacortes-veneer-co.pdf; Berman, Worker-Owned Plywood, 235–36. By 1964, the AVI plant’s two lathes, three dryers, one cold press, and two hot presses produced 128 million square feet.

↑ - 18

“Anacortes Veneer Company,” n.p.; William L. Worden, “Richest Mill Hands in the Country,” Saturday Evening Post, April 5, 1952, 99, in “BIM Plywood Mills 1950s” clipping file, Anacortes Museum; Berman, Worker-Owned Plywood, 106.

↑ - 19

Before the 1980s, unionized plants also paid comparatively good wages. Richardson noted that while, in the early 1980s, independent mills paid employees five to six dollars per hour, the unionized “Timber Company”—the anonymous corporation of his study—paid eight to nine dollars per hour. Richardson, “Green Chain Work,” 123.

↑ - 20

Becca Robbins, “Family of Man Who Died at Columbia Forest Products Mill Sues Company,” Klamath Falls Herald and News, November 7, 2020, https://www.heraldandnews.com/news/local_news/frankie-crispen-a-klamath-falls-mill-and-a-shocking-death/article_270b95a4-07c3-58e3-8bed-526f9d91fb08.html.

↑ - 21

Troy Jones and Shrawan Kumar, “Occupational Injuries and Illnesses in the Plywood Manufacturing Industry Group 1997–2002: A Descriptive Study of Workers Compensation Board Claims,” International Journal of Industrial Ergonomics 35, no. 3 (2005): 184, 189, 191; “Health Effects from Exposure to Wood Dust,” Workplace Health and Safety Bulletin, Government of Alberta Employment and Immigration, August 2009; OSHA Regional News Release, US Department of Labor, March 21, 2011; “Guard All Pinch Points and Ensure Correct Programming of STOP Buttons,” WorkSafe Bulletin WS 04-04, Workers’ Compensation Board of British Columbia (hereafter WorkSafeBC); “Worker Struck by Mobile Equipment at Plywood Mill,” Incident Investigation Report, WorkSafeBC, 2007; Dave K. Verma et al., “Occupational Health and Safety Issues in Ontario Sawmills and Veneer/Plywood Plants: A Pilot Study,” Journal of Environmental and Public Health, 2010, https://www.doi.org/10.1155/2010/526487; Greenberg, Workplace Democracy, 84-85; Berman, Worker-Owned Plywood. After a 1970s wildcat strike in the Bonner mill in Montana, concessions forced the US Plywood Company to keep nurses in the plant. Besides administering emergency medicine, they regularly tested workers for their hearing, treated work-related problems like repetitive motion injuries, and monitored chronic respiratory issues such as asthma. See “Health and Safety,” Working in the Mill Series, Bonner Area History Roundtable, part 6, DVD 05302, accessed in Special Collections, Mansfield Library, University of Montana, Missoula; US Department of Health, Education, and Welfare, NIOSH Health and Safety Guide for Plywood and Veneer Mills (Washington, DC: GPO, 1977), 8, 19, 23–24.

↑ - 22

“Wood Dust Occupational Hazard,” Ohio State University Extension, AEX-595.1-2006, 1; David F. Goldsmith and Carl M. Shy, “Respiratory Health Effects from Occupational Exposure to Wood Dusts,” Scandinavian Journal of Work, Environment & Health 14, no. 1 (1988), 1; “Health Effects from Exposure to Wood Dust,” Workplace Health and Safety Bulletin, 5; Johanne Cote et al., “Occupational Asthma Caused by Exposure to Neurospora in a Plywood Factory Worker,” British Journal of Industrial Medicine 48, no. 4 (1991): 279–82; P. Kurttio et al., “Chromosome Aberrations in Peripheral Lymphocytes of Workers Employed in the Plywood Industry,” Scandinavian Journal on Work, Environment & Health 19, no. 2 (1993): 134. Finnish conifers—not fir—seem to show that exposure to wood fumes—either fresh or from drying—might cause “increased chromosome aberrations,” possibly associated “with an elevated risk of cancer.” Kurttio et al., “Chromosome Aberrations,” 134. The American Conference of Governmental Industrial Hygienists (ACGIH) has listed wood dust as a “confirmed” human carcinogen, and the National Institute for Occupational Safety and Health (NIOSH) lists both hardwood and softwood dust as “potentially carcinogenic to humans.” OSHA, however, only regulates wood dust as a “nuisance.” “Wood Dust Occupational Hazard,” Ohio State University Extension, AEX-595.1-2006, 1, 6. Although 1960s studies of English woodworkers established a clear link between hardwood dust and adenocarcinoma, the association between cancer and softwood particles is less clear. Hildesheim et al. suggest that nasopharyngeal cancer was associated with occupational exposure to softwoods. “Wood Dust Occupational Hazard,” Ohio State University Extension, AEX-595.1-2006, 1; “Health Effects from Exposure to Wood Dust,” Workplace Health and Safety Bulletin, 7; Allan Hildesheim et al., “Occupational Exposure to Wood, Formaldehyde, and Solvents and Risk of Nasopharyngeal Carcinoma,” Cancer Epidemiology, Biomarkers & Prevention 10, no. 11 (2001): 1149; Wood Dust and Formaldehyde, vol. 62, IARC Monographs on the Evaluation of Carcinogenic Risks to Humans (Lyon: IARC/World Health Organization, 1995), n.p.; US Department of Health, Education, and Welfare, NIOSH Health and Safety Guide for Plywood and Veneer Mills, 7, 22.

↑ - 23

Otis Seal, Plywood Plant DVD; EIS Bonner Mill, 4; “Outbreak of Glue Itch,” Science News Letter, July 17, 1943, 44; Georgia-Pacific Plywood Co. v. Department of Labor and Industries, Supreme Court of Washington, November 25, 1955, 47 Wn. 2d 893, 290 P.2d 718, 47 Wash. 2d 893 (Wash. 1955), https://casetext.com/case/georgia-pac-etc-v-dept-l-i; Wouter Fransman et al., “Respiratory Symptoms and Occupational Exposures in New Zealand Plywood Mill Workers,” Annals of Occupational Hygiene 47, no. 4 (2003): 287–95; “Wood Dust Occupational Hazard,” Ohio State University Extension, AEX-595.1-2006, 1; “Health Effects from Exposure to Wood Dust,” Workplace Health and Safety Bulletin, 4; US Department of Health, Education, and Welfare, NIOSH Health and Safety Guide for Plywood and Veneer Mills, 20–21.

↑ - 24

Peder Daugbjerg, “Is Particle Board in the Home Detrimental to Health?,” Environmental Research 48, no. 2 (1989): 161–62; V. F. Garry et al., “Formaldehyde in the Home,” Minnesota Medicine 63 (1980): 107, 109; Richard Daniel Carbone, “Formaldehyde Exposure in Mobile Homes” (MS thesis, University of Washington, 1978), 109–12; Fransman et al., “Respiratory Symptoms and Occupational Exposures in New Zealand Plywood Mill Workers,” 294, 290; Tan Malaka and Arthur Kodama, “Respiratory Health of Plywood Workers Occupationally Exposed to Formaldehyde,” Archives of Environmental Health 45, no. 5 (1990): 288–94; “Formaldehyde,” in Report on Carcinogens, 12th ed. (Washington, DC: National Toxicology Program, Department of Health and Human Services, 2011); Wood Dust and Formaldehyde, vol. 62, IARC Monographs on the Evaluation of Carcinogenic Risks to Humans; Jerome Lavoue et al., “Formaldehyde Exposure in U.S. Industries from OSHA Air Sampling Data,” Journal of Occupational and Environmental Hygiene 5, no. 9 (2008): 575–87. Wood dust may have compounded the cancer risk from formaldehyde. Timo Partanen, “Formaldehyde Exposure and Respiratory Cancer: A Meta-analysis of the Epidemiologie Evidence,” Scandinavian Journal of Work, Environment & Health 19, no. 1 (1993): 8–15. Plywood might also have shaped newly forming bodies beyond the actual workplace. For a British Columbia study, see A. F. Olshan et al., “Paternal Occupation and Congenital Anomalies in Offspring,” American Journal of Industrial Medicine 20, no. 4 (1991). In addition, nasopharyngeal cancer has been associated with leukemia.

↑ - 25

Christopher Sellers, “Factory as Environment: Industrial Hygiene, Professional Collaboration and the Modern Sciences of Pollution,” Environmental History Review 18, no. 1 (1994): 55–83.

↑ - 26

“Publishers [Forest Products Company] Submits Anti-pollution Plan,” Anacortes American, May 31, 1978; “Publishers Gets Variance,” Anacortes American, January 15, 1975; “Feds Found Powerless to Enforce Mill Ruling,” Anacortes American, May 21, 1978; “Regulators Order Mill to Halt Cinder Emissions,” Anacortes American, December 20, 1989, all in “BIM Plywood Mills 1950s” clipping file; “Remedial Investigation Report for Interim Action Work Plan Custom Plywood Site, Anacortes, Washington,” prepared by AMEC under agreement between the Washington State Department of Ecology and GBH Investments, LLC, September 2011, 9 (hereafter cited as RI Report).

↑ - 27

RI Report, 12–14; “Health Consultation: Fidalgo Bay, Anacortes, Skagit County, Washington,” prepared by the Washington State Department of Health under a Cooperative Agreement with the Agency for Toxic Substances and Disease Registry, February 25, 2010, 9, accessed October 18, 2021, at https://www.doh.wa.gov/portals/1/Documents/Pubs/334-223.pdf. In 1989, the Washington State Department of Ecology fined Custom Plywood, owner of the former AVI mill, for dumping formaldehyde resin glue into Fidalgo Bay. “State Fines Plywood Firm … ,” Anacortes American, December 20, 1989, Clipping File, Anacortes Museum.

↑ - 28

RI Report, ES-1-2. As part of an effort to clean up Puget Sound, Washington’s Department of Ecology and its partners identified Fidalgo Bay as a priority. After assessment of the plywood mill site, in 2011, crews began removing contaminated soils, eliminating residual debris, restoring wetlands, and revegetating shorelines. In 2021, the area was in the final cleanup phase (dredging sediments containing toxins and capping them with soil). For complete documentation of the environmental assessments and mitigations, see “Custom Plywood Mill,” Department of Ecology, State of Washington, accessed October 17, 2021, at https://apps.ecology.wa.gov/gsp/Sitepage.aspx?csid=4533.

↑ - 29

RI Report, 82, ES 1-4, ES 13, 20.

↑ - 30

RI Report ES-2, 17, 46; Draft Final Phase II—Interim Intertidal and Selected Subtidal Remedial Action Interim Action Work Plan—Cleanup Action Plan and Engineering Design Report Custom Plywood Site, Anacortes, Washington, August 15, 2012, 2-5.

↑ - 31

RI Report, 23, 60–63, 92–93; “Information Sheet 1: Dioxin—Summary of the Dioxin Reassessment Science,” Environmental Protection Agency sheet included in RI Report; Rachael McDonald, “Fish Kill Likely Caused by Mill Fire,” July 24, 2014, NPR for Oregonians, KLCC.org, https://www.klcc.org/post/fish-kill-likely-caused-mill-fire.

↑ - 32

Lynn Compas and Faith Haney, “Archaeological Monitoring and Inadvertent Discovery Plan for the Custom Plywood Interim Remedial Action Phase II Intertidal and Subtidal Zones, Skagit County, Washington,” prepared for Hart Crowser, Inc., and Washington State Department of Ecology, August 15, 2012, 6–7; “Health Consultation: Fidalgo Bay, Anacortes, Skagit County, Washington,” prepared by Washington State Department of Health, February 25, 2010, 9, included in RI Report; “Bioaccumulative Toxics in Subsistence-Harvested Shellfish-Contaminant Results and Risk Assessment,” prepared by the Swinomish Tribe, December 1, 2006, 3, included in the RI Report; “Human Health Risk Assessment Addendum for the Custom Plywood Interim Addition Work Plan,” Memorandum from Hun Seak Park to Brad Helland, July 2, 2012. The different forms of dioxin are undergoing reevaluation as to what levels of the toxin might cause cancer.

↑ - 33

Richard P. obituary.

↑ - 34

“Uneven Development,” The Dictionary of Human Geography, ed. R. J. Johnston et al., 4th ed. (Oxford: Blackwell, 2000), 867–69. Cultural interpretation of the built environment began with the work of Henry Glassie, the field’s founding father. He states that “nature was made to submit utterly to the ideas of men.” Henry Glassie, Folk Housing in Middle Virginia: A Structural Analysis of Historic Artifacts (Knoxville: University of Tennessee Press, 1975), 130.

↑